Electric motor efficiency – Calculation and comparison between different efficiency class

Efficiency of a motor is a measure of amount of current and voltage which gets converted to useful mechanical power. It is expressed in numerical values of 4 digits including 1 decimal place as a percentage & the value should be less than 99% only. When the energy wasted as heat, friction or in any other form is less, the motor is more efficient thus ensuring lower cost of operation or higher saving for a business or manufacturing company. In simple terms, the efficiency of a motor is useful output power divided by input power. The difference in these two being losses due to factors such as magnetic/electrical

heating and other mechanical losses. An efficiency of 85-90% is good for up to 10 HP motors, but it is expected to have 90% & above efficiency for motors. Above 15 HP in the current market scenario.

The standard electrical motor efficiency is calculated using the formula:

η = (0.7457 × hp × load)/(P[i]), where η=efficiency, hp=rated motor horsepower, load=Output power as a % of rated power, and Pi=input power in kW. The factor 0.7457 converts horsepower to kilowatts.

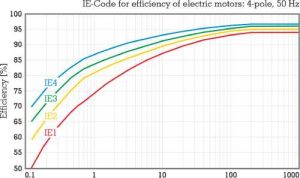

From the above graphs it is clear that the percentage of energy saving is more at lower power rating (kW) between IE1 & IE4. This gap gradually narrows down as the power rating increases. However, even though the percentage difference is small, amount of energy saved will be significantly high being higher kW motors. Hence it is always recommended to use IE4 motors for energy-intensive applications and also for the applications which require about 24×7 operations and thereby consuming lot of energy.